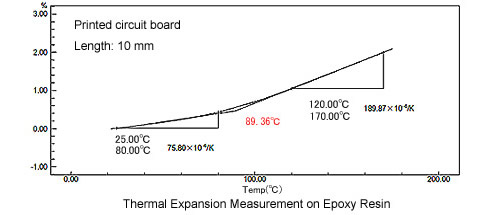

Thermal Expansion Measurements of Printed Circuit Boards (TMA)

The coefficients of thermal expansion are extremely important for parts where metals join epoxy resin, such as printed circuit boards and ICs. Ideally, the difference in thermal expansion coefficients should be as small as possible between the two materials. The measurement of thermal expansion of epoxy resin is introduced below. The curve shown is the thermal expansion curve for a printed circuit board heated at 5°C/minute measured by a TMA-60 Thermomechanical Analyzer. The coefficient of thermal expansion can be seen to differ significantly before and after the inflection point due to glass transition observed near 90°C.

TMA-60 Thermomechanical Analyzer

Thermomechanical analysis involves measuring a physical property under programmed temperature control to determine the relationship between the property and temperature.

Examples of the evaluation of the physical properties of electronic materials include measurement of glass transition and the melting process by DSC, measurement of thermal expansion and the softening point by TMA, and quantitation of fillers and heat-resistance measurements by TGA.